[email protected]

+91 97269 26402

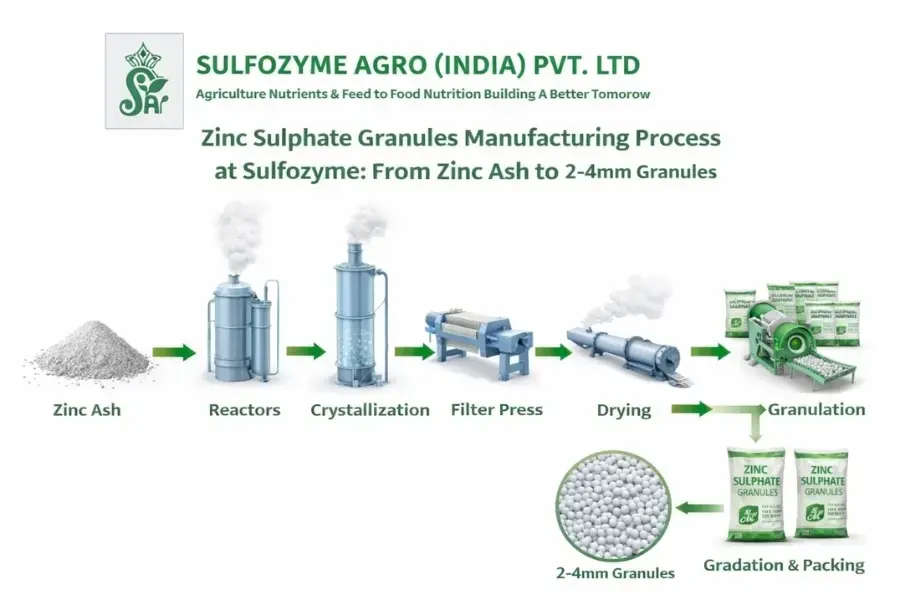

Zinc Sulphate Granules Manufacturing Process at Sulfozyme: From Zinc Ash to 2-4mm Granules

Zinc Sulphate Granules Manufacturing Process at Sulfozyme: From Zinc Ash to 2-4mm Granules

Hey there, farmers and industry enthusiasts! If you’re passionate about the nuts and bolts of agriculture and want to understand how the fertilizers that power your crops come to life, you’re in for a treat. As someone who’s dedicated to sharing knowledge that helps you make informed choices, I want to reassure you that diving into the world of zinc sulphate granules isn’t just fascinating-it’s empowering. Today, we’re exploring the meticulous manufacturing process at Sulfozyme, one of the leading zinc sulphate manufacturers. From humble zinc ash to perfectly sized 2-4mm granules, I’ll guide you through it all in a clear, step-by-step way. Let’s get started and uncover how this essential micronutrient is crafted with care.

What Are Zinc Sulphate Granules and Why Do They Matter?

Before we jump into the process, let’s set the stage. Zinc sulphate is a vital compound used in agriculture to combat zinc deficiencies in soil, boosting crop health and yields. It’s especially crucial for plants like wheat, rice, and maize, where zinc helps with enzyme functions and overall growth. But why granules? Unlike powders that can clump or dust, zinc sulphate granules are uniform, easy to handle, and release nutrients steadily. At Sulfozyme, we specialize in producing high-quality granules, typically sized at 2-4mm, ensuring they’re ideal for broadcasting or mixing into fertilizers.

As an expert in this field, I can confidently say that choosing the right form of zinc sulphate makes all the difference. These granules are water-soluble, eco-friendly, and tailored for farmers who value efficiency. If you’ve ever wondered about the journey from raw materials to your fields, stick around-it’s a story of precision and innovation.

Overview of Sulfozyme's Manufacturing Process

At Sulfozyme, we’re proud to be a trusted name among zinc sulphate manufacturers, with a process that’s both efficient and sustainable. Our journey starts with zinc ash-a byproduct from zinc smelting-and transforms it into premium granules through a series of controlled steps. This isn’t just production; it’s about creating a product that supports healthier soils and bountiful harvests. Let’s break it down step by step, like a friendly tour guide showing you the ropes.

Step 1: Sourcing and Preparing Raw Materials – The Zinc Ash Foundation

It all begins with sourcing high-quality zinc ash, which is rich in zinc oxide. At Sulfozyme, we partner with reputable suppliers to ensure purity-typically around 60-70% zinc content. This ash comes from industrial processes, making our manufacturing eco-conscious by repurposing waste.

Once sourced, the zinc ash undergoes initial preparation. We crush and grind it into a fine powder, removing impurities like iron or lead through screening. This step is crucial for consistency. Think of it as laying a strong foundation: without clean raw materials, the final product won’t perform. Our team uses advanced equipment to handle large batches, ensuring scalability for farmers worldwide.

Step 2: Purification and Chemical Reaction – Turning Ash into Sulphate

Now, the magic happens. The purified zinc ash is reacted with sulphuric acid in a controlled environment. This exothermic reaction produces zinc sulphate solution, along with water and heat. The formula is simple yet precise: ZnO + H₂SO₄ → ZnSO₄ + H₂O.

At Sulfozyme, we maintain optimal conditions-temperature around 80-100°C and pH levels monitored closely-to maximize yield and minimize waste. This step is where expertise shines; our engineers use automated systems to prevent over-reaction, ensuring the solution is pure and ready for the next phase. It’s reassuring to know that every batch is handled with care, prioritizing safety and quality.

Step 3: Crystallization – Forming the Base Crystals

With the zinc sulphate solution ready, we move to crystallization. This involves cooling the solution slowly to allow zinc sulphate monohydrate crystals to form. We use evaporators to concentrate the solution, then cool it in crystallizers. The result? Fine crystals that are the building blocks of our granules.

Why is this step important? Crystallization determines the purity and solubility of the final product. At Sulfozyme, we achieve over 99% purity, making our zinc sulphate granules highly effective. It’s a testament to our commitment to excellence-farmers rely on this for reliable nutrient delivery.

Step 4: Granulation to 2-4mm Size – Shaping the Granules

Here’s where the granules take shape. The crystals are fed into a granulator, where they’re mixed with binders and shaped into uniform 2-4mm pellets. This size is perfect-not too small to dust or too large to dissolve unevenly. We use rotary drum granulators or extrusion methods, depending on the batch, to ensure round, durable granules.

Quality control is key here. We check for size distribution, moisture content, and hardness. These granules are designed to release zinc slowly, providing long-lasting benefits to crops. As a zinc sulphate manufacturer, Sulfozyme prides itself on consistency-every granule meets the mark for easy application in fields.

Step 5: Drying, Cooling, and Packaging – The Final Touches

After granulation, the granules are dried in rotary dryers at controlled temperatures (around 100-150°C) to remove excess moisture, preventing clumping. Cooling follows, then sieving to separate any oversized or undersized particles.

Packaging is the last step: we use moisture-proof bags or bulk containers, labeling them with usage instructions and safety info. This ensures the zinc sulphate granules reach farmers in top condition, ready to enhance soil health.

Quality Control and Standards at Sulfozyme

Quality isn’t an afterthought-it’s embedded in every step. As authoritative experts, we adhere to international standards like ISO 9001 and conduct rigorous testing for purity, solubility, and heavy metal content. Our lab analyzes samples at each stage, using techniques like atomic absorption spectroscopy. This means you can trust Sulfozyme’s products for safe, effective use. We’re reassuring you that our process minimizes environmental impact, with waste recycled where possible.

Benefits of Sulfozyme's Zinc Sulphate Granules

Why choose us? Our granules offer superior solubility, uniform size for even spreading, and high zinc content (up to 36%). They’re versatile for soil or foliar application, boosting crop yields by addressing deficiencies head-on. Farmers love the ease-less mess, better results. Plus, as a leading zinc sulphate manufacturer, we offer competitive pricing and custom formulations.

Why Choose Sulfozyme as Your Zinc Sulphate Manufacturer?

In a world of options, Sulfozyme stands out for our customer-centric approach. We’re not just producers; we’re partners in your success. With years of experience, we provide educational resources, reliable supply, and support. If you’re looking for zinc sulphate granules that deliver, we’re here to help you decide confidently.

There you have it-a behind-the-scenes look at how Sulfozyme crafts zinc sulphate granules from zinc ash to 2-4mm perfection. It’s a process rooted in expertise, care, and a commitment to farming’s future. By understanding this, you’re better equipped to choose products that truly support your land. If you have questions or need recommendations, reach out-we’re here to guide you. Here’s to stronger crops and thriving farms!